DESCRIPTION

Castrol Aircol PD oils are a range of compressor oils, based upon highly refined mineral

oils, which are intended for the lubrication of both reciprocating and rotary air

compressors.

Aircol PD compressor oils have excellent oxidation resistance and low carbon-forming

tendencies and meet the requirements of the DIN 51506 VD-L classification of

lubricants for compressors having air discharge temperatures up to 220ºC.

APPLICATIONS

Castrol Aircol PD compressor oils also have sufficient anti-wear performance, as

measured in the FZG Gear Test, to allow their use in certain screw compressors where

drive between the screws is transmitted by the rotor faces themselves. Castrol Aircol

PD oils exhibit excellent water separation characteristics, allowing condensation formed

within the compressor to readily separate from the oil and minimizing the risk of

emulsions causing premature oil separator element blockage. Aircol PD grades are also

fully inhibited against corrosion, preventing corrosion within the compressor when

operating under humid conditions. The modern tendency in air compressor design is

towards higher capacities from smaller units, with higher loads and temperatures

leading to greater demands upon the lubricant.

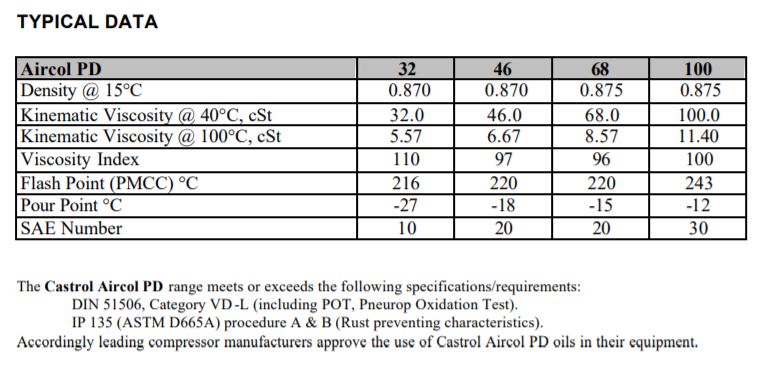

Castrol Aircol PD compressor oils are available in a wide range of viscosities, to suit

different types of compressors operating in varying ambient temperatures. Selection of

the required viscosity grade should be based upon the compressor manufacturers

recommendations for the appropriate ambient temperature range, which will have been

chosen to provide the best compromise between maintaining a fluid film between the

working surfaces and minimizing the amount of power absorbed by fluid friction in this

oil film. As a generalization, however, at normal ambient temperatures Aircol PD 32 and

Aircol PD 46 are suitable for oil-flooded rotary compressors, whilst Aircol PD 68 and

Aircol PD 100 would be selected for the crankcase and cylinders of reciproc ating

compressors. Aircol PD 150 is recommended for sliding-vane compressors, or for

reciprocating units at high ambient temperatures.

BENEFITS

ß Excellent oxidation stability - prolonging the life of the oil in service at higher

temperatures.

ß Maximum wear protection - ensuring longer maintenance and overhaul intervals.

ß Minimum carbon formation-resulting in less risk to fire and explosives, as well as

reduced valve replacement and delivery pipework cleaning.

ß Lower oil consumption.

ß Superior protection against rust and corrosion.

ß Easy starting at low temperatures.

ß Highly refined mineral oil - minimizes health and safety hazard.

ß Wide viscosity range - allows for compliance with machine manufacturers’

specifications.